"It’s kind of a magical thing for me,” says Jack Oclee-Brown, KEF’s head of acoustics. “You get a magnet, a bit of paper and a bit of wire, and you can make a speaker.”

Jack’s PhD in loudspeaker acoustics suggests it might not be quite that simple.

KEF has been putting magnets, bits of paper and bits of wire together for the past 55 years at its headquarters in Maidstone, Kent. It’s still in the same buildings it used when ex-BBC electrical engineer Raymond Cooke started the company in 1961, and it still follows his philosophy: make the speakers sound as natural as the original performance.

Jack is in charge of making absolutely sure that happens.

So he’s the living embodiment of KEF’s tone, then? No. “The KEF sound comes from the technology, in a sense,” Jack says. Imagine the speaker industry organised in a long line from technical to pure artistry – KEF is resolutely at the engineering end of the spectrum.

That all started when the company did. “It was founded by an engineer,” says managing director Steve Halsall. “He founded it because the company he was working for was using late–1950s paper cone technology. That was fine for mono speakers – but when stereo came around, you suddenly wanted two speakers to measure exactly the same. Raymond realised the paper cones of the day just weren’t controllable enough to be able to do that.”

A new set of standards

So he experimented. Raymond brought new materials to the party: more stable materials, such as plastic, that would give a better stereo image. The company he was with at the time wasn’t having any of it, so he went and set up KEF to pursue those avenues by himself. “During the 1960s, KEF was famous for thoroughly researched, scientific designs – designs that genuinely tried to make the sound better,” says Steve.

And that’s why, on KEF’s site, there’s an array of purpose-built testing facilities, including an anechoic chamber (an insulation and acoustic wedge-filled five-metre cube that’s so quiet you can hear your own heart beating) and an impulse-response room (a massive, high-ceilinged concrete cathedral of a space). “KEF was the first to use a computer to measure a loudspeaker,” Jack says. “This room was built specifically for that – to measure the response of the speaker to a little click.”

The room is so big because you need to get the speaker far enough from the walls and floor to measure it accurately. There are hoists and pneumatic lifts and clamps and microphones suspended from other pieces of equipment – all for a click. But that click is absolutely crucial for seeing how a prototype is behaving.

“Before computers, you’d use a plotter: you’d put the speaker in the anechoic chamber, put different frequencies through it, and you’d plot. A pen would draw the measurement on a piece of paper. So if you wanted to store it, you’d put it in a filing cabinet. If you wanted to send someone the frequency response, you’d fold it up and put it in an envelope. If you wanted to compare two speakers or do production measurements with several, you’d have to use a light table. A big light table and a guy with a lot of patience,” says Jack.

The process was so laborious that production control using acoustic measurements was rare. Computers, and KEF’s first Fourier Transform analyser, changed that in 1974. “It’s a standard type of computer analysis,” says Jack. “Your phone can do it nowadays, but at the time you had to buy this big huge box – it was about £250,000 even back then.”

Spending the equivalent of £2.5million in today’s money shows KEF’s total commitment to Getting It Right.

Why? “Because that’s what keeps you going,” Steve says. “You’re always trying to get that 0.1% closer to what reality sounds like. Once you get it working and you hear things on recordings you never noticed before, the hairs on the back of your neck stand up.” Getting It Right means emotion; conveying that performance to the listener.

Getting It Right also means prototypes, testing, analysis, tweaking, sketching… all of which can now be done virtually. Even as recently as the turn of the millennium it was tricky to model, say, a tweeter on a computer; you just didn’t have the horsepower available. “I’m running a model now that will take about ten hours – but you’d have had no chance of doing that in 2000,” says Jack.

Testing simple models on computers means putting a turbocharger on development times. You can find out if you have the tweeter dome the exact right shape; the cabinet the right size; the ports; the crossover; the glue that holds the thing together. All exactly right. And then you can build a prototype.

But it isn’t just a case of plugging in a few measurements and seeing what happens. “If you lump everything into a computer model, it’s just as complicated as looking at the real thing and trying to figure out what’s going on,” says Jack.

The team realised that they could isolate a component virtually to see what it’s doing: whether the issue is an acoustic one, or a mechanical thing; maybe it’s even the air behind the dome. “So you tell the computer the dome is perfectly rigid – something impossible in real life – and see if that gets rid of the problem,” adds Jack.

How to Get It Right

He brings up a model on his computer – it’s a pie-slice of a midrange driver, complete with suspension, basket, motor and cone material. Jack shows how changing the size of the driver, the cabinet and the port all affect the response graph. “It’s a very quick sketchpad. You can quickly work out the basic parts and parameters for the thing you’re designing. Then you add more and more detail.”

The system uses pictorial schematics to assemble the speaker’s innards, and then spits out a graph – which can be manipulated however the engineer wants. Want to make the cone impossibly rigid? Click. Result. Want a ten-foot cabinet with a six-inch driver just to prove to feature-writers that it’ll never work? Click. Result. Want to place a virtual microphone in a virtual room to test the virtual speaker’s off-axis performance? (“Microphones are free when they’re virtual, so I’ve put loads of them in!”) Click. Result.

It’s those experiments that let Jack and his team iterate quickly and efficiently, drilling down to iron out problems before they ever make it to prototype stage or, god forbid, the factory floor.

You can set it going overnight, then get back to your desk in the morning and see if you’ve cracked it. This has transformed the way KEF works. “Probably the key product in terms of really showing what we could do was the Uni-Q and the original Muon,” Jack adds.

Say hello to Uni-Q

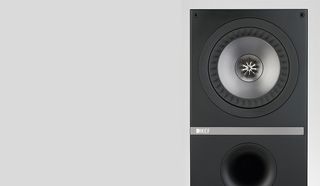

The Uni-Q: the point-source driver. The jewel in KEF’s acoustic crown. It was invented in 1988 to solve the timing problems you get when sound from a tweeter placed a few inches away from the midrange driver reaches your ear at a different time from the midrange sound. It’s a minuscule difference, but it affects the sound negatively – especially when you’re sitting off to the side of the speaker.

The Uni-Q driver places the tweeter at the exact centre of the midrange driver and removes that ‘sweet spot’. The sound comes from a single point in space, there’s no muddying of the acoustic waters, and you get a more natural performance.

In theory. “It had a load of issues,” says Steve. “In the very beginning it wasn’t a good hi-fi drive unit, but because the idea was great, it was developed and developed. It’s probably in its 13th or 14th generation now – and all the issues have been solved. It’s delivering on the concept’s promise.”

And more recently, that development was done virtually. “Before the Muon we had a Reference range with a Uni-Q driver and a hypertweeter,” says Jack.

Backing up a Uni-Q with another tweeter? Surely that’s almost an admission of defeat? “That’s exactly how I feel. We learned that you need to put everything in the computer model or it won’t work properly. The next Uni-Q could do everything the hypertweeter/Uni-Q arrangement could do, but in one driver. And it was point-source. That was a turning point for the whole technology – of saying, ‘this can work better than discrete drivers if you get everything right’.”

Making science beautiful

Uni-Q has taken the point-source concept to an extreme with the Blade series (which has a single unit on its rounded front, flanked by force-cancelling drivers on its tapered sides), but Jack stresses that the key is to make products that people enjoy listening to: “We see it as a technical device that’s meant to reproduce a sound going in”.

But it has to look as good as it sounds, he adds, which is why they collaborate with people like superstar industrial designer Ross Lovegrove. “We worked with him on the Muon and the Muo. You can give him a really complicated brief and he’ll come back with six or seven ideas – completely different – and they’ll all work. We could use any of them.”

Everything is engineered and designed at KEF’s site in Kent. Everything is tested and developed there. Jack and his team are responsible for anything that affects the speakers’ sound. And when it comes to the high-end speakers that the company builds in its small factory, what they say, goes: “For something like a Reference or a Blade speaker we can have really strict requirements for where drivers are, shapes, volumes and construction.”

Jack shows a picture of an MDF Blade Two prototype they made in the workshop to prove that it sounded good. “It looked pretty ugly. The brief says which surfaces need to be smooth, but it doesn’t say what the shape is going to be. This one didn’t have the subtle curvature of the finished model; it didn’t fade in towards the bottom. You wouldn’t ask me to design it, basically!”

Design engineer Phil Gidley is the chap who has to translate what Jack and the designers produce into something that can actually be manufactured. “And that goes for every little part,” he says, rotating an insanely complicated CAD model of a Blade 2 on his screen. “We can assemble all these parts together, make sure that things meet together and don’t interfere.”

It’s aerospace tech, essentially, adapted for the acoustics world – and it makes that prototyping process far easier. “It’s fairly difficult to convey a shape like the Blade on paper,” Phil says, adding, “The CAD is very tweakable, so we can get around the screen and change it until we get things right; you can even see how the light hits it and so on.”

They send the CAD off for rapid prototyping (3D-printing on steroids) and then double-check the fit, form and function. Not quite right? Tweak the CAD and re-send.

“In the old days, that would’ve gone straight off to tooling and could have meant spending thousands of pounds on modding the tooling if it wasn’t right. Now we trap that kind of thing. In lots of ways we can cut down the design cycle and improve the quality of the product by having more design iterations before going for the final part,” says Phil.

It’s essential for all sides of the department to work in harmony. “I can’t do what Phil does, and Phil can’t do what I do,” says Jack. “There’s a lot of expertise here. You have to have a multidisciplinary team: the production, the sourcing, the tooling…”

Phil agrees: “I think you end up with a more cohesive product, because it isn’t designed by committee. If you’ve got one person looking after that aspect of the design, I think you tend to end up with a better product.”

No compromise

Over in the factory, quality manager Dan Fowler is in charge of ensuring all that work is carried out perfectly, every time. His team of nine puts together all of KEF’s high-end products: the Reference, Blade and Muon speakers. “The crew is brilliant. They’re so committed and passionate. Each speaker is built individually – Graham tests them, and then a certificate is printed out with the builder’s name on it. ‘Built by Mark Abbott’.”

It’s those personal touches that remind you that, while KEF might be a global brand with some speakers costing as much as a house, it’s still a proud, tight-knit team doing the graft. Mel Matthews, an assembly technician, might be hand-building Blade crossovers one day, and assembling drivers the next; Graham Humphries, the assistant production manager, painstakingly tests up to 50 speakers a day against a reference line-standard model in a dedicated acoustic booth; Jon O’Toole, another assembly technician, lavishes care on endless Blade 2 speakers as they pass through his workstation.

They’re all polished, checked, buffed, checked again, carefully packed in situ and then shipped off across the world.

It’s got to be 100%

“They really care about what they’re building,” Dan says. “They get frustrated when they get poor-quality cabinets in, you know, that kind of thing. You can see their passion coming out when they get angry – I understand it, because they’re committed. We don’t mess about trying to buff out mistakes; we send it straight back. Everything’s got to be 100 per cent.”

KEF takes this uncompromising approach to everything it does: its research, its design, its engineering, its manufacture. It even hand-picks acoustics graduates from UK universities – graduates like Jack. Raymond Cooke started KEF in response to people settling for the imperfect. His legacy – plain to see in every department – has resulted in some of the most spectacular speakers ever made.

“The company is as good as the people that work here, and I think what’s interesting is the number of people who’ve worked here ten years plus,” says Jack. They’re all after a bit of that magic, it seems. Magic that’s still made in Maidstone.

No nonsense: KEF’s acoustic approach

Raymond Cooke wasn’t one for faffing about. He started his career as an industrial chemist, then joined the Royal Navy as a radio operator in WWII before completing an Electrical Engineering degree and moving on to the BBC’s Engineering Designs Department.

Working alongside some of the world’s greatest acoustic designers spurred Raymond on to pursue a more scientific direction. It was a time where speaker design was more fly-by-the-seat-of-your-pants than test-analyse-test-analyse; so after spending five more years honing his craft at Wharfedale he left to start his own company to do just that.

KEF was all about engineering, materials technology, logic and advances in measurement techniques.

“The first things he made had really weird technology in,” says Jack Oclee-Brown, KEF’s head of acoustics.

“It speaks of how he wanted to do new things, and engineer new materials.”

Raymond didn’t just keep it to himself: he was president of the Audio Engineering Society in 1984, and won its silver medal in 1993 for outstanding contributions to transducer measurements.

That philosophy of experimentation, rigorous analysis and free flow of ideas informs everything KEF does today.

The LS50 anniversary speaker: designing a new classic

“We were going to produce a speaker for our 50th anniversary,” says Steve Halsall, KEF’s MD. “It was going to look slightly retro, but with modern technology inside.”

But when the company’s owner – himself from an industrial design background – saw it, he wasn’t happy. “He said, ‘Take me back to the original LS3/5A. What was special about that product?’ I said, ‘The guys that designed it at the BBC – two of the best acoustic designers who ever lived – both happened to be there at the same time’.”

Back in 1975 they came up with a mini-monitor that blew everyone else’s away. The LS3/5A showed a total understanding of the art and science of speaker design.

“He said, ‘OK, have we been to our engineers and told them to develop something like that?’ I told him, ‘Well, no. We’ve just had a brief to produce a 50th anniversary product.

“So he made us go back. We had to completely develop it so it sounded good first, looked good second. You never usually get that opportunity. But the poor industrial designers had to deal with that big, bulbous baffle – which was essential for the sound.

“We wanted anybody who was interested in a nice-sounding small speaker to be able to afford it,” Steve says.

And now, five years after the anniversary, the LS50 is still shifting in huge numbers.

For more information, visit uk.kef.com >>